<fieldset id="ica6m"></fieldset>

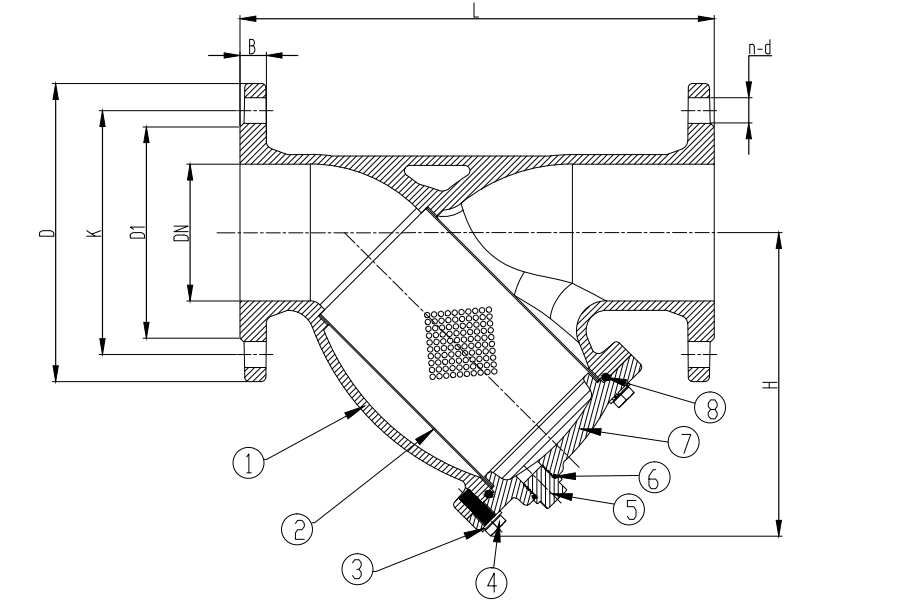

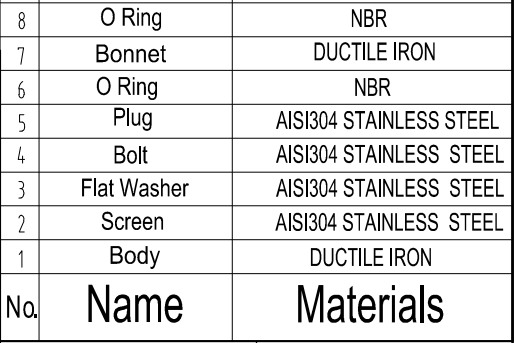

Y type Strainer is the filtration equipment which is to prevent impurities in the flow media from flowing into the back-end equipment. The strainer is usually being installed before the Water.

Features:

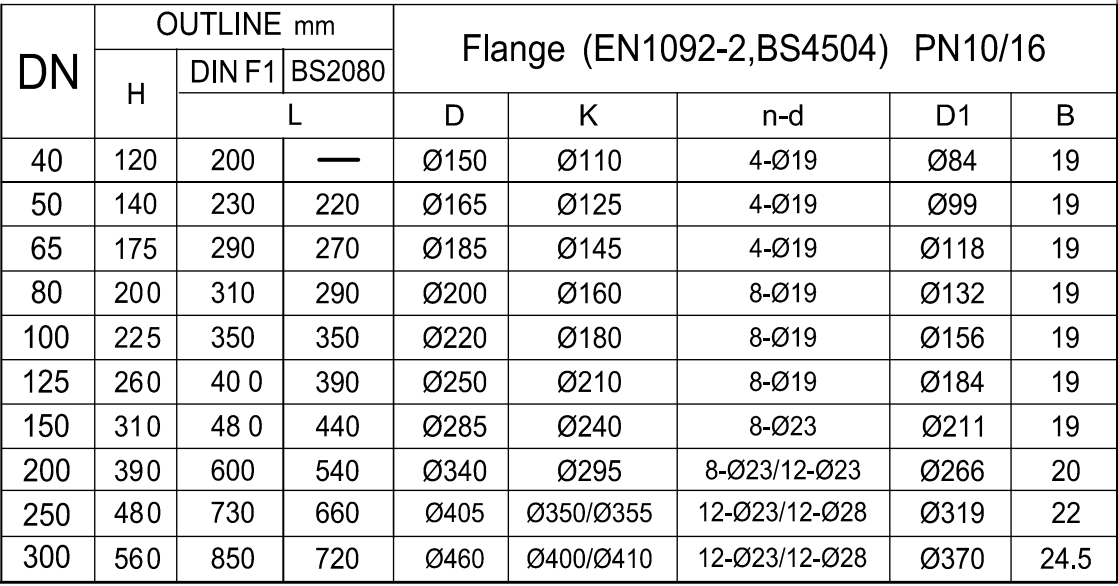

?- Face to face: DIN3202-F1 / BS 2080

?- Flanges: BS4504 / EN 1092-2 PN10/16

?- Pressure Rate: PN10/16

?- Hydraulic pressure test to EN12266? 1.5 x PN

?- Coating: Fusion bonded epoxy coating

?- Medium: Neutral water, Drinking water, Sewage

?- Temperature Range: 0℃ - 80℃

?- Bonnet and cover bolts are in A2-70 (AISI 304),

?- Coating - Electrostatically applied fusion bonded epoxy coating inside & outside for excellent corrosion resistance. Standard color RAL 5005, other colors upon request.

?- Designed and built to widely recognized standards.

?- 100% testing before packing and delivery

Storage & Maintenance

1. For long-term storage Y Strainer should be placed in a cool dry place, not allow to be stored or stacked in the open air.

2. Installation:

(1) Check whether the working condition is matched with the strainer pressure, temperature, corrosion resistance or not before installation;

(2) Attention should be paid that the flow direction of the medium should be in line with the arrow direction on the valve body when installing the strainer;

(3) Both sides of the flange connections must be parallel and coaxial;

(4) Check all the fasteners are loose, damaged or not;

(5) Fasten the flange bolts symmetrically and alternately;

(6) The daily sewage treatment can be done as long as removing the sewage bolts;

(7) After long-term use by extracting the sewage cover can do the filter for cleaning and remove the retained impurities on the screen.

Technical Data

Copyright ? IVALVE TECH. (TONGLING) CO.,LTD. All rights reserved.